Designing a custom case to protect sensitive equipment involves more than just choosing the right materials and dimensions. It’s crucial to ensure the case can withstand the various shocks and environmental conditions it will encounter during its lifecycle. At Packaging Strategies Inc., we prioritize rigorous testing to guarantee our cases provide optimal protection. Here, we explore the importance of shock and environmental testing in case design and how it benefits your equipment.

The Importance of Shock Testing

Shock testing is a critical aspect of case design. It simulates the impacts and vibrations that a case may experience during transportation and handling. This type of testing ensures that the case can absorb and dissipate energy from sudden impacts, preventing damage to the contents.

Understanding Shock Testing Procedures

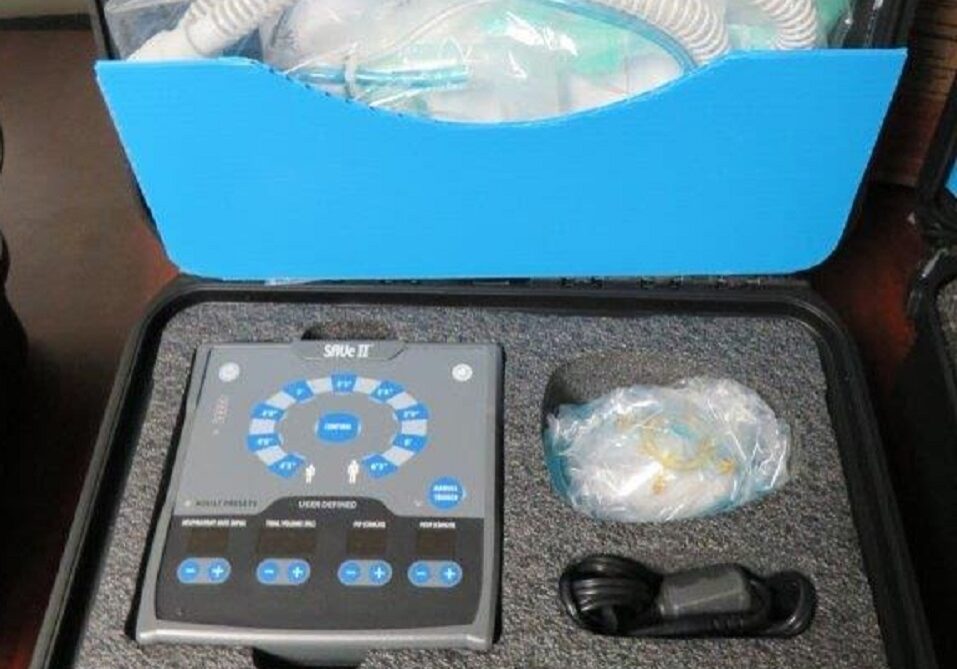

Shock testing typically involves dropping the case from various heights and angles onto hard surfaces to replicate real-world conditions. The goal is to evaluate how well the case and its internal cushioning protect the equipment. High-quality cases are designed with materials and structures that can absorb shock, such as impact-resistant plastics and custom foam inserts. By subjecting cases to rigorous shock testing, we can identify possible weaknesses and make necessary adjustments to enhance durability.

Benefits of Shock Testing

Shock testing provides several benefits, including:

- Enhanced Durability: Identifying and reinforcing weak points ensures the case can withstand rough handling.

- Improved Protection: Testing guarantees that the internal cushioning effectively absorbs shocks, safeguarding sensitive equipment.

- Peace of Mind: Knowing that your case has passed stringent shock testing gives you confidence in its ability to protect your valuable equipment during transit.

Environmental Testing: Simulating Real-World Conditions

Environmental testing assesses how well a case can protect its contents under various environmental conditions, including temperature extremes, humidity, and exposure to water and dust. This type of testing ensures that the case can maintain its integrity and protect the equipment in challenging environments.

Key Environmental Testing Methods

- Temperature Testing: Cases are exposed to high and low temperatures to evaluate their ability to protect equipment from thermal stress. This is particularly important for electronic devices that can be sensitive to temperature fluctuations.

- Humidity Testing: This test assesses the case’s resistance to moisture and its ability to prevent condensation, which can damage sensitive equipment.

- Water and Dust Ingress Testing: Cases are tested for their ability to keep out water and dust, ensuring that the contents remain dry and clean. This is crucial for cases used in outdoor or industrial environments.

Benefits of Environmental Testing

- Reliable Protection: Environmental testing ensures the case can protect equipment from harsh conditions, extending its lifespan and functionality.

- Compliance with Standards: Many industries have specific standards for environmental protection. Testing ensures that the case meets these requirements, ensuring compliance.

- Adaptability: Knowing how a case performs in various conditions allows for design improvements that suit a more comprehensive range of environments.

Let Packaging Strategies Inc. help you protect your equipment with expertly designed cases that withstand the most challenging conditions.

Depend on Packaging Strategies for Your Custom Packing Needs

Packaging Strategies has assembled a team with over 100 years of experience in design, engineering, development, manufacturing, and sales. We created the Packaging Strategies Design and Technology Center to create and manufacture complete systems integration packages and container solutions of all sizes and materials for our clientele. Many of these clients are federal agencies or in the private sector. No matter what you need to carry, Packaging Strategies is sure to have the right case for the job. You can view our website here, and follow us on Facebook, Twitter, Flickr, and LinkedIn.