Custom case engineering is essential for industries that need to simultaneously transport and easily protect sensitive equipment. At Packaging Strategies Inc., we specialize in designing custom cases that meet the specific needs of our clients across industries like medical, military, and aerospace. Creating a custom case is complex, involving a range of advanced technologies and thoughtful design principles. In this blog, we’ll break down the four essential components of custom case engineering that allow us to deliver reliable, high-quality solutions.

3D Modeling

3D modeling is the foundation of our custom case engineering process. This technology allows us to create precise digital representations of the equipment housed in the case. By using exact measurements and high-resolution scans, we can ensure a snug and secure fit for every item, no matter how complex its shape.

Through 3D modeling, we can experiment with different case layouts, foam inserts, and configurations before creating a physical prototype. This not only saves time but ensures accuracy and eliminates errors. By visualizing the final design in a digital space, we can quickly adjust and refine the case to meet the client’s specific requirements. The result is a custom case that fits perfectly and offers maximum protection.

Custom-Shaped Foam

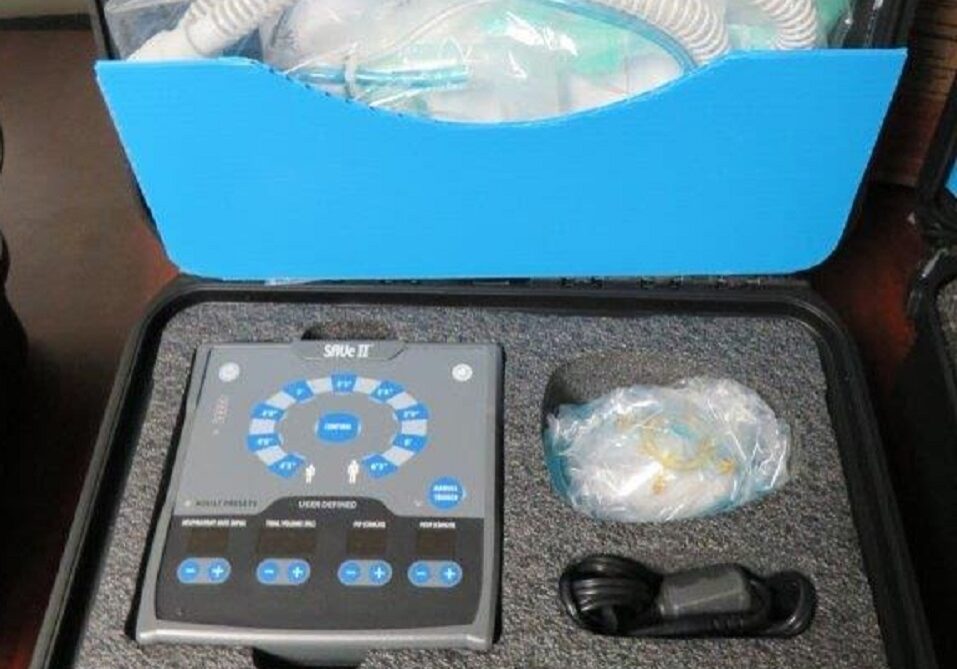

Custom-shaped foam interiors are essential for securing equipment inside the case and preventing any movement during transit. Whether the case is designed for delicate medical instruments, military electronics, or high-value communications equipment, custom foam ensures that each item is held firmly in place.

At Packaging Strategies, Inc., we use a range of foam types, densities, and configurations to match the needs of each project. The foam is cut and shaped to fit the exact contours of the equipment, providing both cushioning and support. This custom fit minimizes the risk of damage from impacts, drops, or vibration, offering a high level of protection during transport. The versatility of custom foam also allows us to create multi-layered cases with different compartments for various equipment, enhancing organization and accessibility.

Impact and Shock Testing

Custom cases need to withstand a variety of environmental challenges, from rough handling during transportation to extreme weather conditions. We conduct rigorous impact and shock testing as part of the custom case engineering process to ensure our cases are up to the task. This testing simulates the conditions the case will face in real-world environments, allowing us to identify potential weaknesses and adjust accordingly.

By performing these tests, we can guarantee that the case will protect its contents from drops, bumps, and other physical impacts. Environmental testing also ensures that the case materials can endure heat, cold, moisture, and dust exposure. Thorough testing gives our clients peace of mind, knowing their equipment will remain safe no matter where it’s transported.

Close Partnership with the Client

One of the most critical components of custom case engineering is the close partnership we develop with each client. We understand that every project is unique, and our clients know their equipment better than anyone. That’s why we prioritize open communication and collaboration throughout the design process.

From the initial consultation to the final product, we work closely with our clients to meet their specific needs. We can provide advice on materials, adjust the case design to accommodate new equipment, and ensure compliance with industry standards. This collaborative approach helps us create cases that meet technical requirements and align with the client’s operational goals and preferences.

Whether you need a case for sensitive medical equipment or military-grade gear, Packaging Strategies, Inc.’s custom case engineering process ensures your equipment is protected at the highest level.

Depend on Packaging Strategies for Your Custom Packing Needs

Packaging Strategies has assembled a team with over 100 years of experience in design, engineering, development, manufacturing, and sales. We created the Packaging Strategies Design and Technology Center to create and manufacture complete systems integration packages and container solutions of all sizes and materials for our clientele. Many of these clients are federal agencies or in the private sector. No matter what you need to carry, Packaging Strategies is sure to have the right case for the job. You can view our website here, and follow us on Facebook, Twitter, Flickr, and LinkedIn.