When it comes to producing a strong and reliable custom case for your equipment, there are certain characteristics to look for. Your custom case should be sturdy, airtight, watertight, and created with quality materials. While some materials are ideal for creating a custom case, other materials should be avoided when making a new case. Here is a closer look into custom case materials.

Custom case materials to avoid when creating a new case include:

1. Plywood- While plywood may seem like a sturdy and environmental friendly option; this material will fail to provide the strength and durability needed for your custom case. Plywood will become weak and vulnerable to mold and rot should it travel to a humid area. Damage to the case could also allow moisture into the case, causing serious damage to your equipment.

2. Plastic- Plastic is a very commonly used material in many popular industries; however it should not be on your list for custom case materials. Plastic becomes vulnerable when exposed to extreme materials, meaning it won’t be able to hold up in extreme conditions. Heat will cause the case to melt while cold will cause the case to crack.

3. Wood Laminates- Similar to plywood, these materials are unable to handle extreme travel conditions. Wood laminates cannot stand up to the changes in humidity, temperature, and overall travel conditions, leaving your expensive and essential equipment vulnerable to irreplaceable damage.

Custom case materials to reach for when creating a new case include:

1. Aluminum- When it comes to quality custom case materials, aluminum is the best way to go. Aluminum is sturdy enough to withstand travel conditions without the fear of a crack or chip in the case. Aluminum can also withstand changes in temperature and humidity while never leaving your equipment vulnerable.

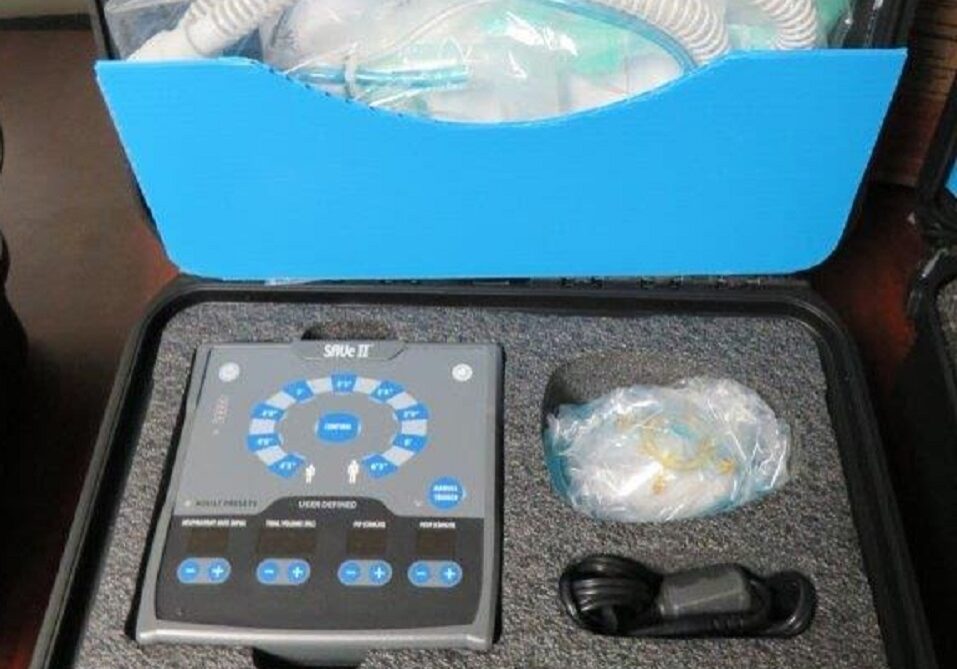

2. Foam Interiors- If you want to increase the protection surrounding your equipment, choose custom foam interiors to fit into your aluminum case. Foam interiors will keep your equipment safe from shock vibrations while also helping to monitor temperature.

At Packaging Strategies Incorporated, we create custom aluminum cases to protect the important equipment held inside. We know how essential a custom aluminum case is when transporting equipment for military and medical purposes. We pride ourselves on creating cases that meet every need of our customer while also exceeding their expectations, at a price that is affordable and reasonable. We are also proud of our service to every arm of the Department of Defense and United States military.

To get started with a custom military case from PSI, call us today at 888-774-7557. You can also visit our contact page online.

Follow Packaging Strategies Incorporated today on LinkedIn, Google+, Facebook, and Twitter.

Source:

http://goo.gl/kF1Qxt